Polyurethane Enameled ọla kọpa aluminom waya klaasị180

| Ụdị ngwaahịa | UW/180 |

| Nkọwa zuru oke | 180Grade kwụ ọtọ welded polyurethane |

| Ntuziaka IEC | IEC 60317-51, IEC 60317-20 |

| Ndekọ okpomọkụ (°C) | 180 |

| Ịnweta ike | 390 ℃/3s solderable |

| Ntuziaka NEMA | MW 82, MW79, MW75 |

| UL-kwadoro | EE |

| Dayameta dị | 0.08mm-1.15mm |

| Ọkụkụ ndakpọ oyi (°C) | 230 |

| Okpomọkụ ọkụ ọkụ (°C) | 200 |

| Dayameta aha (mm) | Nkwenye onye nduzi (mm) | G1 | G2 | voltaji ndakpọ kacha nta(V) | Opekempe elongation (%) | ||

| Ihe nkiri kacha nta | Dayameta mpụta zuru oke (mm) | Ihe nkiri kacha nta | Dayameta mpụta zuru oke (mm) | G1 | |||

| 0.1 | 0,003 | 0,005 | 0.115 | 0.009 | 0.124 | 1200 | 11 |

| 0.12 | 0,003 | 0,006 | 0.137 | 0.01 | 0.146 | 1600 | 11 |

| 0.15 | 0,003 | 0,0065 | 0.17 | 0.0115 | 0.181 | 1800 | 15 |

| 0.17 | 0,003 | 0,007 | 0.193 | 0.0125 | 0.204 | 1800 | 15 |

| 0.19 | 0,003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900 | 15 |

| 0.2 | 0,003 | 0.008 | 0.225 | 0.0135 | 0,238 | 2000 | 15 |

| 0.21 | 0,003 | 0.008 | 0,237 | 0.014 | 0.25 | 2000 | 15 |

| 0.23 | 0,003 | 0.009 | 0,257 | 0.016 | 0,271 | 2100 | 15 |

| 0.25 | 0,004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 15 |

| 0.27 | 0,004 | 0.009 | 0.3 | 0.0165 | 0,318 | 2300 | 15 |

| 0.28 | 0,004 | 0.009 | 0.31 | 0.0165 | 0,328 | 2400 | 15 |

| 0.3 | 0,004 | 0.01 | 0,332 | 0.0175 | 0.35 | 2400 | 16 |

| 0.32 | 0,004 | 0.01 | 0,355 | 0.0185 | 0,371 | 2400 | 16 |

| 0.33 | 0,004 | 0.01 | 0,365 | 0.019 | 0,381 | 2500 | 16 |

| 0.35 | 0,004 | 0.01 | 0,385 | 0.019 | 0,401 | 2600 | 16 |

| 0.37 | 0,004 | 0.011 | 0,407 | 0.02 | 0,425 | 2600 | 17 |

| 0.38 | 0,004 | 0.011 | 0,417 | 0.02 | 0,435 | 2700 | 17 |

| 0.4 | 0,005 | 0.0115 | 0,437 | 0.02 | 0,455 | 2800 | 17 |

| 0.45 | 0,005 | 0.0115 | 0,488 | 0.021 | 0,507 | 2800 | 17 |

| 0.5 | 0,005 | 0.0125 | 0.54 | 0,0225 | 0,559 | 3000 | 19 |

| 0.55 | 0,005 | 0.0125 | 0.59 | 0,0235 | 0,617 | 3000 | 19 |

| 0.57 | 0,005 | 0.013 | 0.61 | 0.024 | 0,637 | 3000 | 19 |

| 0.6 | 0,006 | 0.0135 | 0,642 | 0.025 | 0,669 | 3100 | 20 |

| 0.65 | 0,006 | 0.014 | 0,692 | 0,0265 | 0,723 | 3100 | 20 |

| 0.7 | 0,007 | 0.015 | 0,745 | 0,0265 | 0,775 | 3100 | 20 |

| 0.75 | 0,007 | 0.015 | 0,796 | 0.028 | 0,829 | 3100 | 20 |

| 0.8 | 0.008 | 0.015 | 0,849 | 0.03 | 0,881 | 3200 | 20 |

| 0.85 | 0.008 | 0.016 | 0,902 | 0.03 | 0,933 | 3200 | 20 |

| 0.9 | 0.009 | 0.016 | 0,954 | 0.03 | 0,985 | 3300 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0,0315 | 1.037 | 3400 | 20 |

| 1 | 0.01 | 0.0175 | 1.06 | 0,0315 | 1.094 | 3500 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0,0325 | 1.196 | 3500 | 20 |

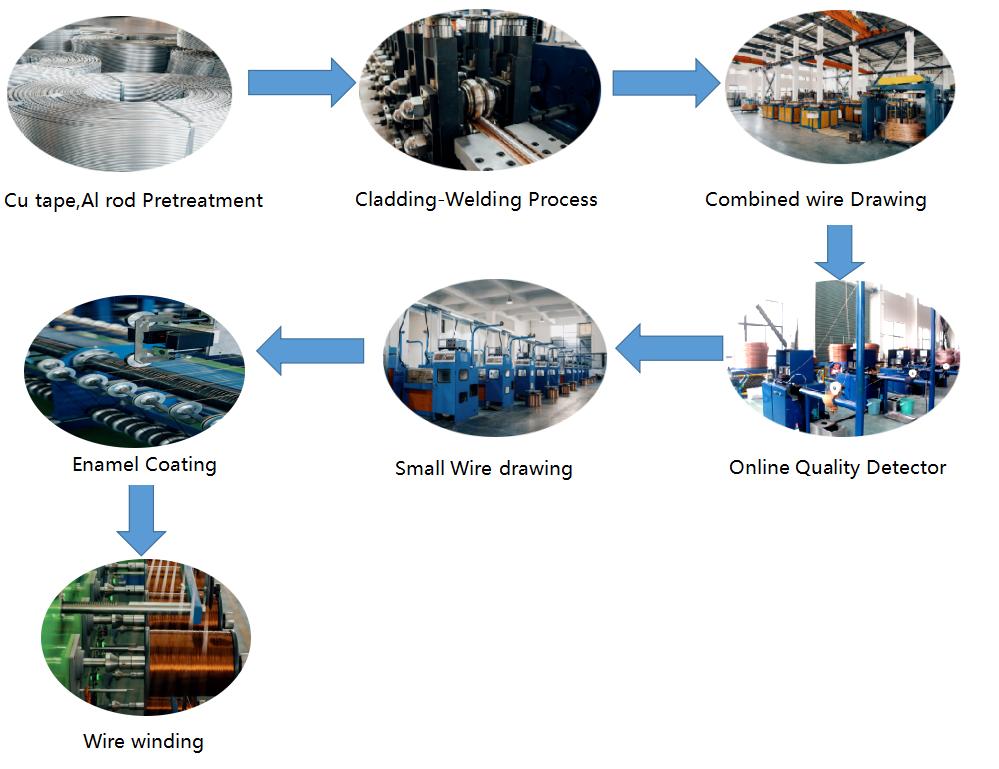

1. Igwe ọkụ eletrik dị mma, dị ka waya ọla kọpa n'ogo dị elu karịa 5MHZ.

2. Chekwaa ihe ọla kọpa ma belata ọnụ ahịa.Njupụta nke waya ọla kọpa kpuchiri aluminom dị obere karịa nke waya ọla kọpa dị ọcha, ogologo ya dịkwa okpukpu 2.5 karịa nke waya ọla kọpa dị ọcha nke otu ịdị arọ.

3. Ntugharị okpomọkụ dị nro dị elu karịa UEW / 155;Igwe ọkụ na-ere ọkụ kwụ ọtọ bụ 390 Celsius;mfe agba;obere dielectric ọnwụ na elu ugboro;enweghị pinhole mmiri nnu

| Ụdị ngwaahịa | Nkọwa zuru oke | Njirimara |

| UW/180 | 180Grade kwụ ọtọ welded polyurethane | okpomọkụ ndakpọ dị nro dị elu karịa UEW/155;Igwe ọkụ na-ere ọkụ kwụ ọtọ bụ 390 Celsius;mfe agba;obere dielectric ọnwụ na elu ugboro;enweghị pinhole mmiri nnu |

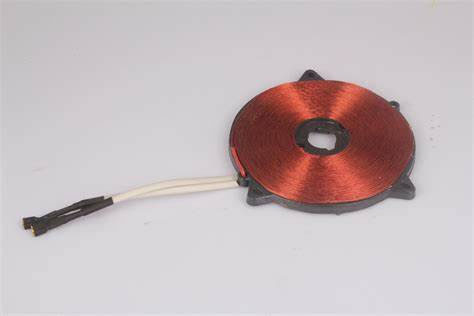

1.Relays, micro-motors, obere ndị na-agbanwe agbanwe, mkpuchi ọkụ, valves nkwụsị mmiri, isi magnetik, mkpuchi maka ngwa nkwurịta okwu.

2.Transformer winding na induction cooker.Ọ nwere ike ibelata ibu ngwaahịa.

3.Induction cooker chassis.Ọ nwere ike belata ọnụ ahịa mmepụta.

4.Sodium oriọna ballast.Ọ nwere ike ibelata ibu ngwaahịa.

5.dị iche iche windings nke aerospace ngwá.Ọ nwere ike ibelata ibu ngwaahịa.

6.Coils na Induction cooker chassis, mgbanaka mgbanaka mgbanaka na ngwa ihe ọdịyo dị elu.

Nhọrọ Bobbin

| Ụdị Spool | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Ibu arọ [g] | nom.arọ waya net [kg] | akwadoro maka nha waya [mm] | spools kwa igbe | |||||

| Waya ọla kọpa enamed | Aluminom Waya Enaled | Enamed CCA Waya | ||||||||||||

| 10% CCA | 30% CCA | 40% CCA | 50% CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04-0.19 | 4 |

| PT-10 | 160 | 22 | 230 | 200 | 180 | 0.45 | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20-0.29 | 2/4 |

| PT-15 | 180 | 22 | 230 | 200 | 200 | 0.54 | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30-0.62 | 1/2 |

| PT-25 | 215 | 32 | 280 | 250 | 230 | 0.75 | 28 | 10 | 11 | 13 | 14 | 15 | 0.65-4.00 | 1 |

| PT-60 | 270 | 32 | 406 | 350 | 300 | 2.05 | 80 | 24 | 24 | 28 | 32 | 35 | 0.65-4.00 | 1 |

Nkwakọ ngwaahịa